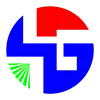

The manufacturing process of TFT LCDs involves several stages, including the array process (TFT process), cell process, and module process.

Each stage requires different manufacturing techniques and equipment to produce high-quality TFT LCDs.

In this article, we provide an overview of the TFT LCDs manufacturing process.

Array Process

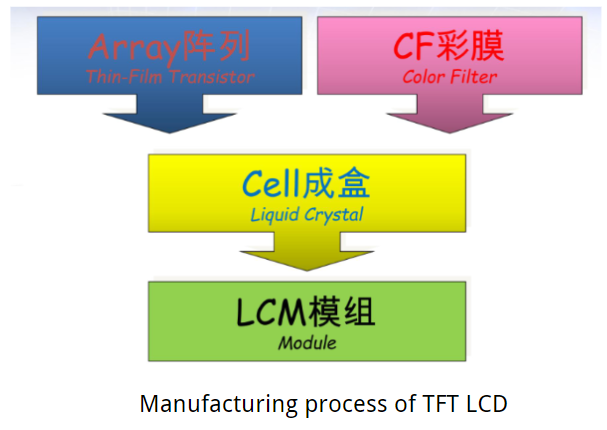

The array process is the first step in the manufacturing of a TFT LCD.

This process involves the creation of a thin-film transistor (TFT) array on a glass substrate.

The TFT array is the foundation of the LCD, and it controls the individual pixels that make up the display.

The array process includes several steps, as follows:

- Grass Substrate Preparation

- Photoresist coating

- Exposure

- Developing and Etching

- Photoresist Stripping

- Checking

Cell Process

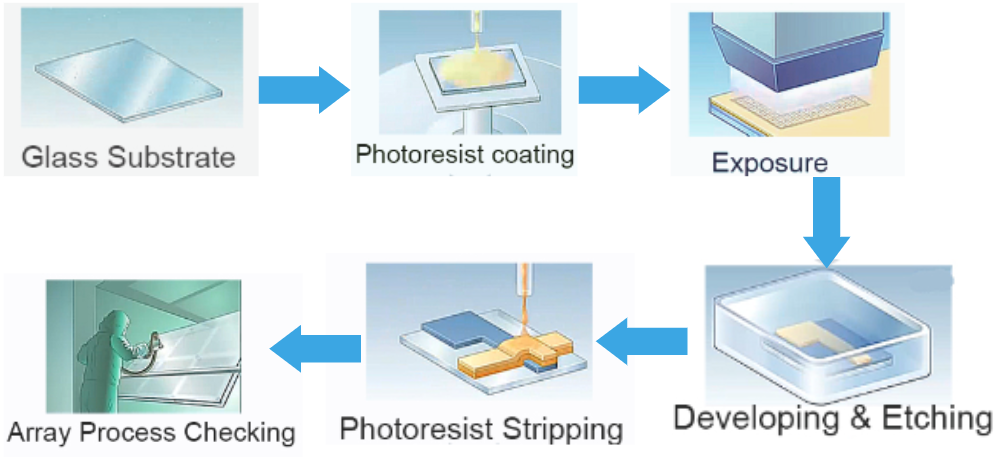

The cell process involves sealing the TFT array between two glass plates to create a liquid crystal cell.

The TFT LCD cell process is a critical step in the manufacturing of thin-film transistor liquid crystal displays (TFT LCDs).

The cell process involves sealing the TFT array between two glass plates to create a liquid crystal cell, which is the core component of the TFT LCD.

This process typically consists of the following steps:

- Cleaning and Preparation of Glass Substrates

- Deposition of Alignment Layer

- Deposition of Spacers

- Deposition of Liquid Crystal Material

- Sealing of the Cell

The TFT LCD cell process is a critical step in the manufacturing of TFT LCDs, as it involves creating the liquid crystal cell that forms the core component of the display.

Module Process

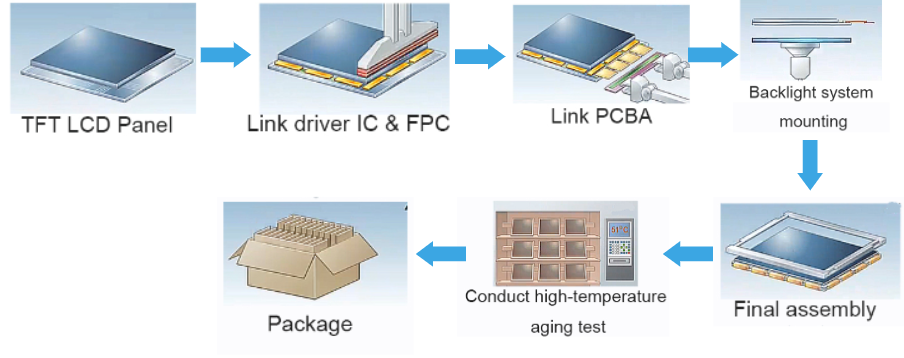

The module process is the final stage in LCD manufacturing, where the LCD cell is assembled with other components to create the final LCD module.

The module process includes several steps, as follows:

- Backlight Assembly

- Driver IC Mounting

- FPC Bonding

- Test and Inspection

- Packaging and Shipping

Conclusion

In conclusion, the manufacturing process of an LCD involves several stages, including the array, cell, and module processes.

Each stage requires different manufacturing techniques and equipment to produce high-quality TFT LCDs.

The array process involves the production of the active matrix array.

The cell process involves bonding the TFT and CF substrates to create the LCD cell, while the module process involves assembling the LCD cell with other components to create the final LCD module.

By following these manufacturing processes, Hongguang Display can produce high-quality displays for various electronic devices.